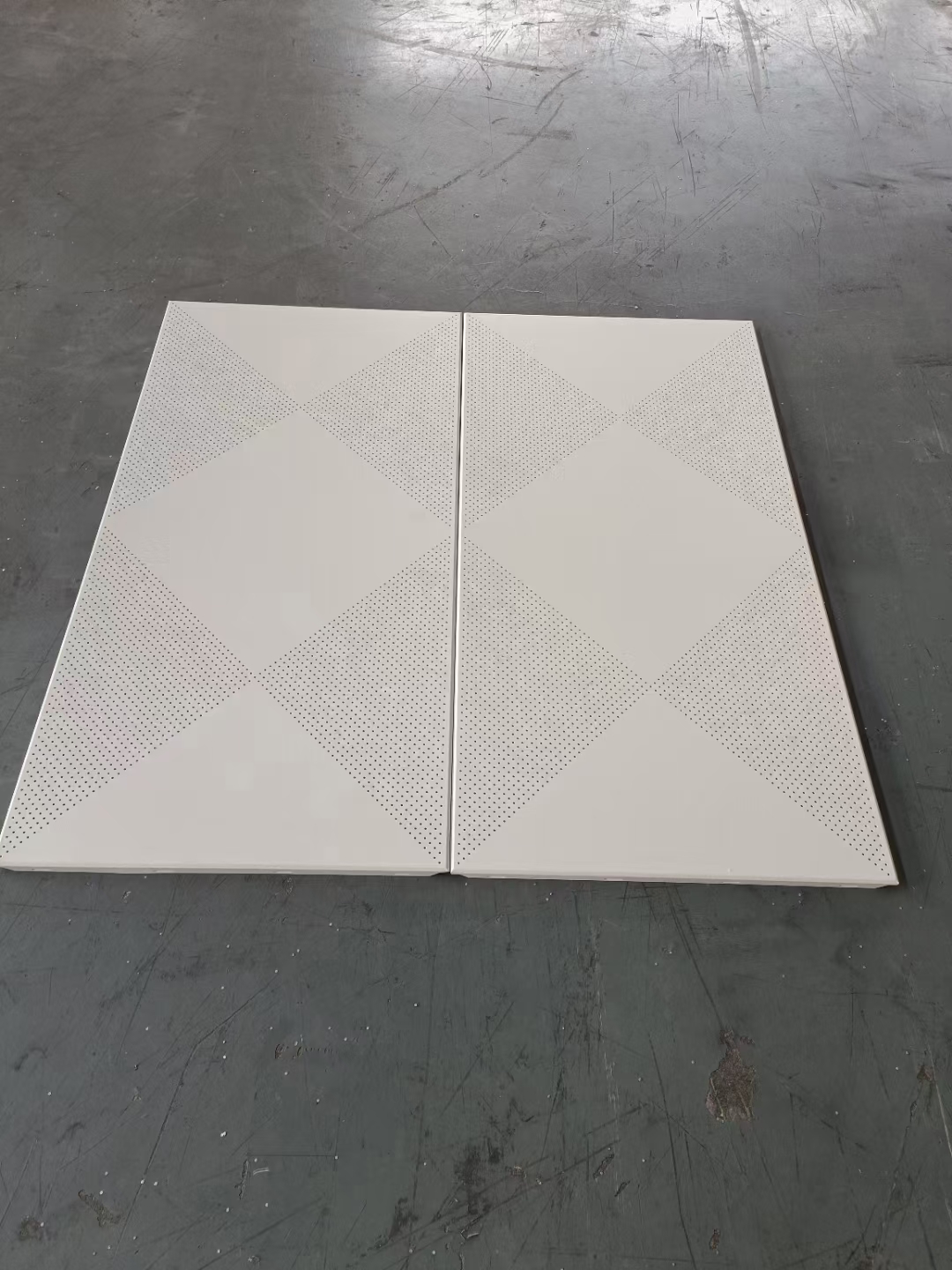

| ITEM | 3D priting Aluminum ceiling panel |

| Product Name | Aluminum Solid Panel |

| Aluminum Alloy | 1100,3003 |

| Panel thickness | 2.0~5mm or customized thickness |

| Max size | 2000*7000mm |

| Surface treatment | PE coated |

| PVDF 2/3/4 Layer coating | |

| Powder coating | |

| Wood grain (wood grain paper /Therminal transfer printing / wood grain painting) | |

| Color | RAL color, |

| Shape | Flat, cambered, double curved, triple curved, spherical, customized shaped. |

| Warranty | Max 20 years guarantee for ideal application evvironment |

| Packaging | Carton package |

| Leadtime | 10-20 days after receiving the deposit and confirm the details |

Usage:

1) Building walls , hotel , ceiling beams, offices , banks, roofs , cladding

2)Airport , station , exhibition center

3)Signboards , commercial center , display platforms , reception hall

Why Aluminum solid panels?

1. Light weight, high strength.

2. Durable and corrosion resistance.

3. Good craftsmanship.

4. Uniform coating and diverse colors.

5. Easy to clean and maintainance.

6. Convenient installation and construction.

7. Fireproof, moisture proof.

8. Recycling, environmental protection.

aluminium honeycomb panel aluminium honeycomb ceiling

aluminium honeycomb panel aluminium honeycomb ceiling

Aluminum Honeycomb ceiling, brand new building material

Aluminum Honeycomb ceiling, brand new building material

Aluminium honeycomb ceiling

Aluminium honeycomb ceiling

GUANGXI SAIYI BUILDING MATERIALS CO., LTD© All Rights Reserved.